In industries where process reliability, chemical resistance, and measurement precision are non-negotiable, radar liquid level sensors provide one of the most advanced technologies for continuous level monitoring. Unlike contact sensors, radar sensors operate using microwave radar waves to measure distance to the liquid surface. This non-contact approach makes them ideal for challenging conditions—such as extreme temperatures, corrosive vapors, foams, and surface agitation. Additionally, radar level sensors are suitable for a broader range of applications and media types, demonstrating their adaptability and versatility across diverse industrial needs. Among the various technologies available, radar level measurement stands out for its exceptional accuracy and reliability. By leveraging advanced radar technology, radar level transmitters provide continuous, non-contact monitoring of liquids and other materials, even in the most demanding environments. These devices, including industry-leading models like the Rosemount 3408 and 5408, deliver high measurement accuracy, making them a preferred choice for applications where precision and safety are paramount. As industries continue to demand higher standards of efficiency and process control, radar level measurement has become an indispensable tool for modern operations.

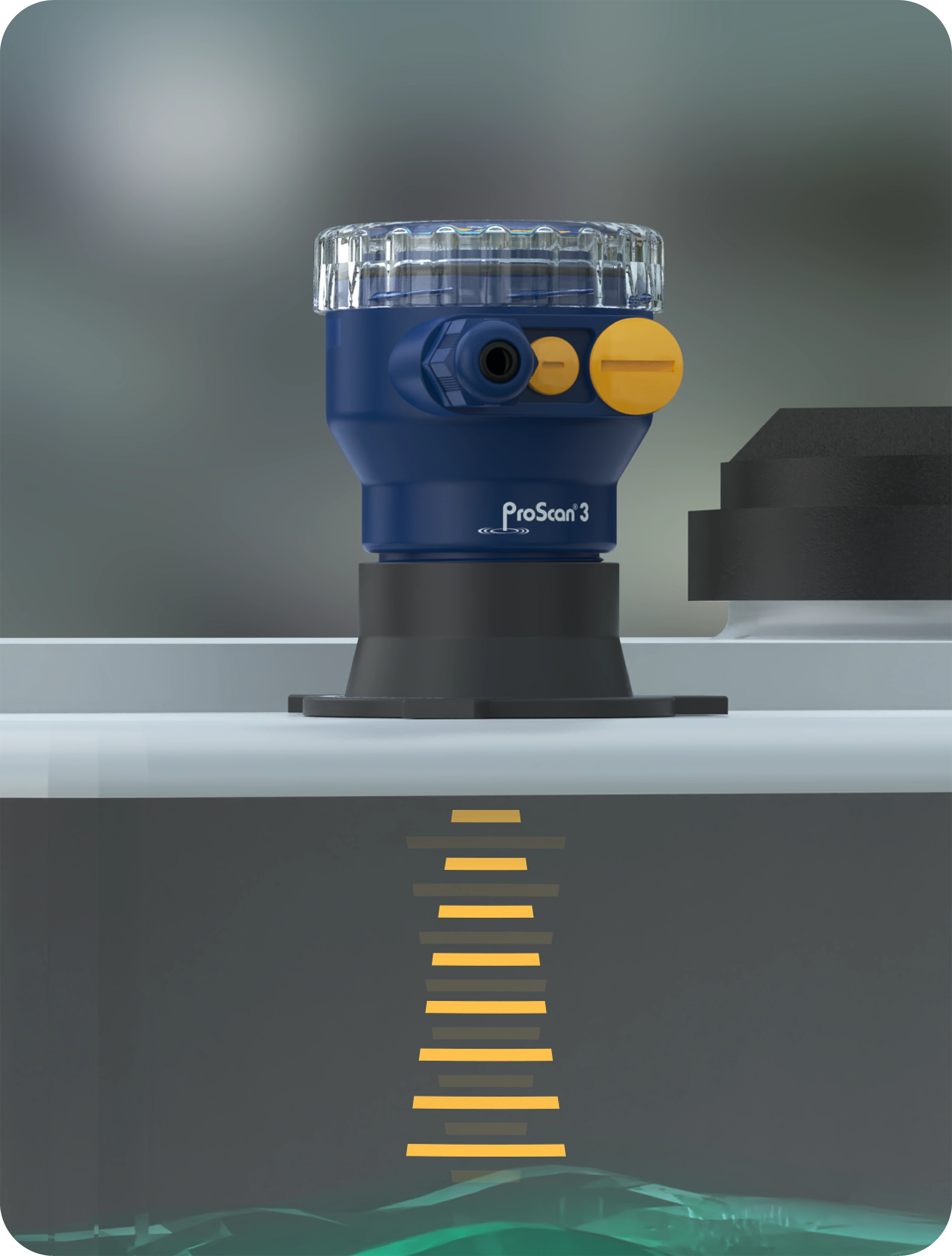

In this guide, we’ll explore how radar level sensors work, their key applications in the chemical industry, chemical manufacturing, food and beverage production, and water and wastewater management, types, common alternative names, and a deep dive into Icon Process Controls’ ProScan radar level transmitter series, including the high-performance ProScan3 80G.

Introduction to Level Measurement

Level measurement is a foundational process in industries such as chemical manufacturing, food and beverage production, and water and wastewater management. Ensuring accurate and reliable level measurement is essential for maintaining safety, optimizing efficiency, and guaranteeing product quality. Whether monitoring the contents of a storage tank or controlling a process line, precise level detection helps prevent overflows, shortages, and costly downtime.

Among the various technologies available, radar level measurement stands out for its exceptional accuracy and reliability. By leveraging advanced radar technology, radar level transmitters provide continuous, non-contact monitoring of liquids and other materials, even in the most demanding environments. These devices, including industry-leading models like the Rosemount 3408 and 5408, deliver high measurement accuracy, making them a preferred choice for applications where precision and safety are paramount. As industries continue to demand higher standards of efficiency and process control, radar level measurement has become an indispensable tool for modern operations.